The automotive world is complex, filled with specialized terms and tools. Few are as vital to modern vehicle maintenance as On-Board Diagnostics, or OBD. If you’ve ever had a “Check Engine” light illuminate your dash, you’ve interacted with this system.

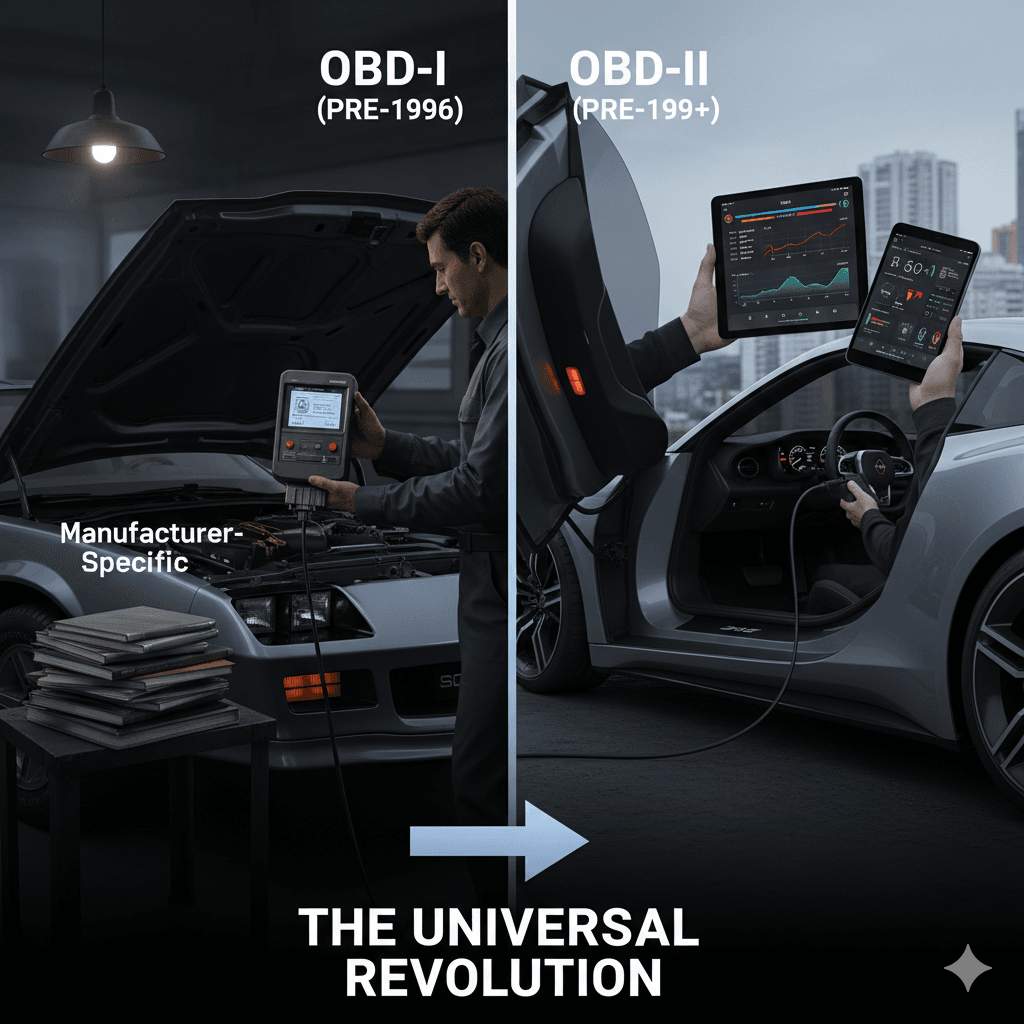

But not all diagnostic systems are created equal. The automotive industry has gone through a significant evolution, moving from the earlier OBD-I standard to the universally adopted OBD2. Understanding the differences between an OBD-I and an OBD-II scanner is crucial for anyone working on, or even just owning, a vehicle from the mid-90s or older.

This post will clearly break down what sets these two generations of diagnostic tools and standards apart and why the transition to OBD-II was a revolutionary step for vehicle maintenance.

The Foundations: What is OBD?

OBD stands for On-Board Diagnostics. It’s the electronic system integrated into a vehicle’s computer that monitors the performance of the engine, emission controls, and other major subsystems. Its primary job is to detect problems, alert the driver (via the infamous Check Engine light), and store diagnostic information.

This information is stored as Diagnostic Trouble Codes (DTCs). A scanner is the essential tool that plugs into the car’s diagnostic port to retrieve, read, and sometimes clear these codes, providing technicians and owners with the data needed to pinpoint and fix an issue.

OBD1: The Pioneering Era (Pre-1996)

OBD-I systems were introduced in the 1980s, primarily to meet initial U.S. government regulations for controlling vehicle emissions. While a groundbreaking step at the time, this first generation had significant limitations, especially when it came to diagnostics.

Lack of Standardization: The Biggest Hurdle

The single most defining characteristic of OBD-I was its lack of standardization.

- Manufacturer-Specific Codes: A fault code on a Ford might mean something completely different on a General Motors or Honda vehicle. This required mechanics to either memorize a vast array of proprietary codes or rely on brand-specific reference materials.

- Unique Connectors: There was no single, universal connector port. Every manufacturer—sometimes even different models from the same manufacturer—used their own unique diagnostic link connector (DLC). These connectors could be rectangular, circular, or even just a set of exposed pins, and they were often located in hard-to-find places like under the hood, behind the glove box, or near the fuse panel.

- Proprietary Scanners: Due to the proprietary codes and connectors, a technician often needed a different, specialized OBD-I scanner for each car make they worked on. Generic scanners were largely non-existent or offered very limited functionality.

Limited Diagnostic Capabilities

OBD-I’s focus was narrow. It primarily monitored basic emissions-related systems and core engine functions. The data output was generally minimal, lacking the real-time parameter streaming that modern systems rely on. Diagnosing an OBD-I vehicle often involved older, more complex, and error-prone methods, such as manually “jumpering” certain pins on the connector to make the Check Engine light flash out the error code.

OBD2: The Universal Revolution (1996 and Newer)

The shortcomings of OBD-I led to the development of the OBD-II standard, which became mandatory for all passenger cars and light trucks sold in the United States starting in 1996 (with similar standards adopted across Europe as EOBD and other regions). This shift brought unprecedented uniformity and diagnostic power.

Standardization: The Game Changer

OBD-II’s main triumph is standardization, which simplified diagnostics for everyone.

- Universal Connector: All OBD-II compliant vehicles use the same 16-pin trapezoidal connector . This port is always located within a specific area of the vehicle’s cabin, usually within three feet of the steering wheel (most commonly under the dashboard on the driver’s side).

- Universal Diagnostic Trouble Codes (DTCs): OBD-II introduced a standardized set of universal trouble codes (e.g., P0300). While manufacturers can still use “enhanced” or proprietary codes, the core DTCs mean the same thing across all makes and models.

- Standardized Communication Protocols: OBD-II defined five primary communication protocols, ensuring all compliant vehicles speak the same diagnostic language.

Enhanced Diagnostic Capabilities and Data

OBD-II scanners offer vastly superior capabilities compared to their predecessors.

- Comprehensive Coverage: OBD-II monitors and reports on a much broader array of systems, including the engine, transmission, ABS (Anti-lock Braking System), airbags, and sometimes even body control modules.

- Real-Time Live Data: A crucial feature is the ability to stream live data—referred to as PID (Parameter ID) data—directly from the vehicle’s sensors in real-time. This is invaluable for diagnosing intermittent or complex problems.

- Freeze Frame Data: When a DTC is set, the OBD-II system captures a “snapshot” of all the live data at that exact moment. This Freeze Frame Data tells the technician the conditions (speed, engine load, temperature, etc.) under which the fault occurred, making diagnosis much more precise.

OBD1 vs. OBD2 Scanners: A Quick Comparison

| Feature | OBD1 Standard (Pre-1996) | OBD2 Standard (1996 and Newer) |

|---|---|---|

| Year Range | Generally 1980s to mid-1990s. | Mandatory from 1996 onward in the US. |

| Connector | Varies by manufacturer; non-standardized. | Standardized 16-pin trapezoidal connector. |

| Connector Location | Highly variable (under hood, glovebox, under dash). | Standardized location (driver’s side under-dash). |

| Diagnostic Codes | Manufacturer-specific (proprietary). | Universal standard codes (P0xxx, B0xxx, etc.). |

| Compatibility | Requires brand-specific or specialized tools. | Works with generic OBD-II scanners across makes. |

| Diagnostic Scope | Limited (primarily basic engine/emissions). | Comprehensive (engine, transmission, ABS, airbags, etc.). |

| Data Access | Minimal data, often required manual interpretation. | Extensive real-time data stream and Freeze Frame Data. |

Choosing the Right Scanner

If you’re in the market for a diagnostic tool, knowing which system your car uses is the first step:

- If your car is a 1996 model or newer (in North America): You need an OBD2 scanner. Thanks to standardization, even an inexpensive, entry-level scanner will read and clear the universal codes.

- If your car is pre-1996: You will need an OBD1 scanner designed specifically for that vehicle’s make and often its specific model year, as the connectors and protocols were not standardized.

The Adapter Confusion

Some tools or adapters claim to let you use an OBD-II scanner on an OBD-I vehicle. Be careful. While an adapter can change the physical plug shape, it does not change the car’s underlying OBD-I communication protocol. For an OBD-II scanner to work effectively on an OBD-I car, it must have the necessary OBD-I software for that specific manufacturer built into it—a feature typically found only in expensive, professional-grade tools. For DIY users, a dedicated OBD-I scanner for your vehicle’s brand is usually the most reliable route for pre-1996 models.

Conclusion: A Revolution in Maintenance

The shift from OBD-I to OBD-II was a watershed moment in vehicle maintenance. While OBD-I laid the groundwork, OBD-II’s commitment to standardization and enhanced data not only made vehicle diagnostics infinitely easier and more reliable but also empowered independent mechanics and vehicle owners.

Today, the ease of simply plugging a generic OBD-II scanner into a standardized port to instantly access rich, real-time data is a convenience we often take for granted—a convenience that makes it much faster and cheaper to keep our modern vehicles running smoothly and meeting strict emissions standards.