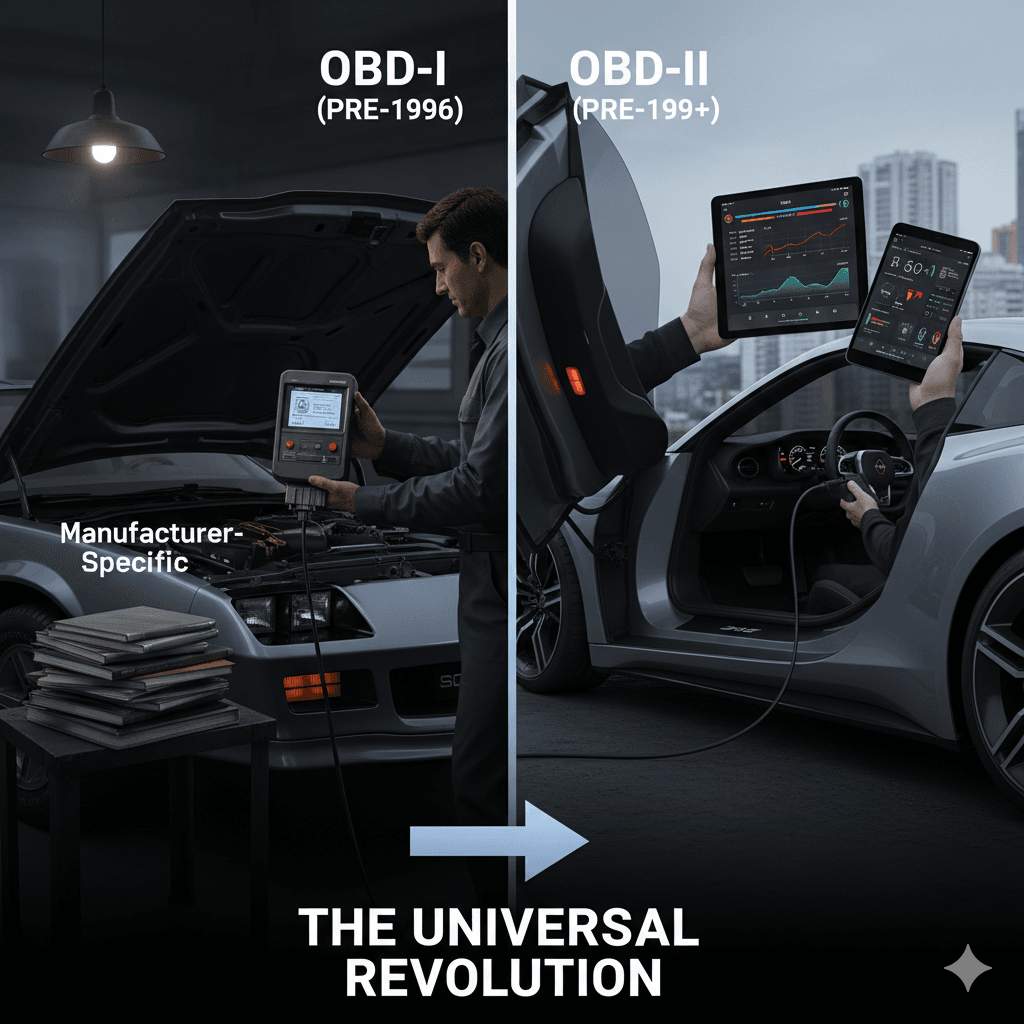

In the rapidly accelerating world of automotive diagnostics, the strategic choice of tools can be the defining factor in a repair shop’s efficiency, diagnostic accuracy, and overall revenue generation. When dealing with the OBD2 (On-Board Diagnostics 2) standard—the universal gateway to vehicle data—technicians face a critical choice between the highly portable and intuitive handheld OBD2 scanner and the feature-rich, deeply analytical PC-based OBD2 software solutions. Both are vital in the modern garage, but their applications and limitations are vastly different. Understanding these nuances is critical for shop owners and master technicians planning their capital expenditure and workflow optimization.

The Power of Handheld OBD2 Scanners: Simplicity and Speed

Handheld OBD2 scanners have long held their place as the essential initial assessment tool. Their design philosophy centers around speed, durability, and plug-and-play functionality, making them the first tool a technician reaches for when a check engine light appears. They excel at quickly accessing the core data mandated by the OBD2 standard, such as P-codes and basic live data streams.

Key Strengths and Limitations Summary

| Aspect | Handheld Scanner Performance | Implication for the Workshop |

| Durability | High: Resistant to drops and shop contaminants. | Lower long-term maintenance/replacement costs. |

| Data Visualization | Low: Small screen restricts complex graphing. | Challenges in diagnosing intermittent or complex faults. |

| Bi-directional Control | Limited/Basic: Primarily focused on generic OBD2 functions. | Scope of high-value repairs is restricted. |

| Portability | Excellent: All-in-one, no external components needed. | Fastest tool for initial vehicle triage. |

Handheld scanners are characterized by their exceptional portability; they are entirely self-contained units that can be effortlessly carried between different work areas or used during dynamic road tests without the burden of managing laptop chargers or external cables. This independent nature ensures the tool is always ready for immediate action.

From a practical standpoint, these tools are significantly more robust. They are purpose-built to withstand the hostile garage environment, including exposure to grease, dirt, and accidental drops, thereby substantially lowering maintenance and replacement costs. The speed of deployment and instantaneous use are unmatched; they boot up instantly and provide rapid reading of DTCs and Freeze Frame Data, which effectively supports quick job triage and prioritization under the OBD2 framework. Furthermore, they often possess a less complex user interface, minimizing the learning curve for new or less-experienced technicians. They also offer operational autonomy, working flawlessly even when the shop’s Wi-Fi network is unstable or unavailable.

Despite their convenience, handheld scanners suffer from significant analytical and functional limitations when moving beyond basic OBD2 compliance. The small screen size fundamentally restricts the technician’s ability to graphically display and compare complex live data streams from multiple controllers, making the diagnosis of subtle, intermittent faults challenging and often relying more heavily on guesswork. Technologically, they frequently lack the necessary processing power and software depth required to execute critical manufacturer-specific functions that lie outside the generic OBD2 protocol, such as extensive Bi-directional Controls (needed to command actuators), Module Coding, and Adaptations.

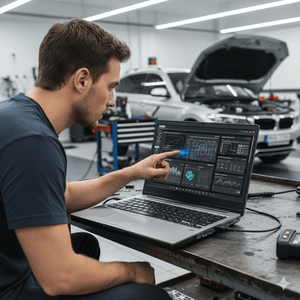

PC-Based OBD2 Software: Depth and Power Integration

PC-based diagnostic systems transform a standard laptop or rugged tablet into a formidable diagnostic workstation. They utilize the general-purpose computing power and large display of the PC, coupled with specialized VCI (Vehicle Communication Interface) hardware, to deliver unparalleled depth and flexibility in analyzing OBD2 data and beyond. These solutions are rapidly becoming essential for any shop specializing in complex electrical and programming work.

Core Advantages of PC-Based OBD2 Solutions

The primary advantage lies in superior visual and analytical power. The large, high-resolution monitor provides ample space to simultaneously view dozens of data parameters, complex wiring diagrams, and technical overlays. This capacity facilitates accurate, data-driven conclusions and minimizes human error when dealing with multi-system faults, even those revealed through the OBD2 data stream.

Crucially, PC-based platforms provide the necessary architecture to run sophisticated functions. They facilitate full module programming (flashing), extensive component adaptations and calibrations (e.g., ADAS systems), and often achieve true OEM-level access via J2534 interfaces. This capability opens the door to high-revenue, complex repair work previously only available at dealerships.

PC software also excels in technical resource integration. The diagnostic environment can directly link to repair manuals, technical service bulletins (TSBs), and online databases, establishing a single-screen ecosystem for both diagnosis and repair planning. The software’s scalability means that the system is highly future-proof, adapting to new communication standards (DoIP, CAN FD) through simple software updates rather than costly hardware replacement.

The most significant trade-off for PC-based systems is durability and mobility. Laptops are highly susceptible to damage from shop contaminants and drops, often necessitating investment in expensive ruggedized computing hardware. Furthermore, they require constant vigilance regarding power management and connectivity.

Strategic Investment: The Hybrid Solution

The most effective strategy for any contemporary, full-service garage is not to choose one system over the other, but to adopt a dual-platform, hybrid approach that maximizes both efficiency and capability.

| Tool Type | Primary Function | Ideal Technician Skill Level | Annual Subscription Cost |

| Handheld OBD2 Scanner | Quick Code Retrieval, Basic Readiness Status, Simple Service Functions. | Apprentice/Mid-Level | Often High (Mandatory for Advanced Features) |

| PC-Based OBD2 Software | Advanced Diagnostics, Module Programming, OEM Protocols, Full System Analysis. | Master Technician/Specialist | Variable (Often Subscription-Based, but potentially cheaper than top-tier handhelds) |

By combining the speed of the handheld OBD2 scanner for routine tasks with the analytical depth of the PC software for complex faults, a repair shop maximizes its diagnostic capabilities. This strategy ensures both rapid service turnaround for routine jobs and possesses the necessary power to tackle the most profitable, complex electronic faults. The analytical power of PC-based OBD2 solutions is rapidly transitioning from a shop luxury to an absolute necessity to remain competitive in the face of increasingly complex vehicle electronics.